Proactive businesses have embraced this new role with cleaner processes that limit environmental impact and give environment-minded consumers more options than ever. But it hasn’t been easy. Here’s a look at the complex evolution of the solvent degreasing process and how the industry is responding to modern regulations and consumer demands.

A Crash Course on Solvent Cleaning Systems

Solvent cleaning systems have long been staples for manufacturers and other industrial operations. It’s easy to see why — it’s effective, easy to standardize across metal materials and relatively inexpensive to operate.

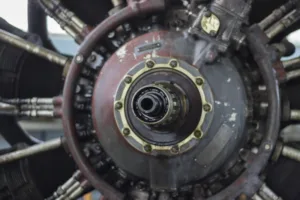

Vapor degreasing, one of the more popular methods, works like this: A combination of lower heating elements and upper cooling coils channel and contain a degreasing agent inside a single machine. A contaminated machine part can be placed into the suspended degreaser vapor, which condenses on the part, encases grease and other contaminants and then drops into a reservoir for recycled use.

More dated solvent degreaser methods use multiple machines and are considered to be less energy efficient and more wasteful of the degreaser products themselves. It’s those processes that forced the hands of regulators. More on that in the next section.

How We Got Here

While solvent degreaser processes have come a long way, it wasn’t a quick transition. It took a combination of new solvent regulations and ingenuity on the part of the industry to get it done.

The push arguably started in the 1980s, when scientists began diving deeper into the environmental impact of the industrialized world. One of the major catalysts was the ozone layer scare. It was theorized that unchecked degreasers and aerosols were contributing to rapid deterioration of that atmospheric layer. The result was a frenzy of new regulations and soul-searching — and it worked.

In the years since, industries have seriously updated how they operate. That new culture of environmentally conscious ingenuity has served forward-thinking companies well, and they tend to be far more prepared for new scientific findings and the consequential regulations.

What Are the Regulations?

Regulations vary across the globe, but the consensus is that industries must rein in the wasted byproducts associated with degreasing. Some have strict recycling requirements, some limit the products that can be used, and others do both.

In the United States, that’s largely dictated by the Clean Air Act. Virtually every type of solvent currently in use is subject to strict guidelines. The Act details ways that degreaser solvents must be reused or disposed. Similarly, the Environmental Protection Agency (EPA) enforces what is known as the Solvent-Contaminated Wipes Rule, which dictates how solvent-contaminated wipes should be handled.

Regulations are under constant review. As new technologies become available, regulations are updated to minimize environmental impact. In that regard, regulators and industries work in tandem to improve degreasing methods.

The Impact on Solvent Cleaning Processes

As noted earlier, some degreasing methods are preferred over others in terms of their environmental impact. So, while the degreasing agents might not drastically change, the processes in which they are used have changed. Notably, vapor degreasing is currently the superior method of degreasing and is setting the standard for clean degreasing processes.

In coming years, expect to see more innovative thinking from the industries themselves. The companies to watch will be the ones who are eager to employ cleaner degreasing equipment such as vapor degreasing.

Which Companies Are Taking the Lead?

Companies such as Enviro Tech have set a high bar when it comes to environmentally friendly degreasing processes. Enviro Tech and other pioneers in this space are already using vapor degreasing technology to recapture degreasing agents while ensuring that manufacturing parts are thoroughly cleaned in the process.

It’s an interesting field, and one that continues to evolve. Learn more about how industries are tackling new environmental challenges by contacting Enviro Tech today.