What Is Vapor Degreasing?

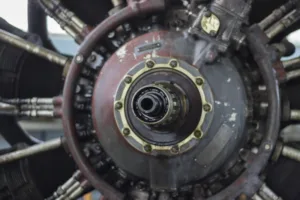

Vapor degreasers clean machinery parts and components by coating them with a degreasing solvent suspended in a heated vapor. When the vapor cools, the degreasing agents — along with any unwanted grease or grime — drips into a reservoir below, leaving your parts dry and clean. Because the process allows the solvent to get deep into the crevices of components, it’s one of the most effective and efficient ways to ensure your machined parts are thoroughly cleaned.

Is Vapor Degreasing Safe?

Yes. But as with any machinery or equipment, it is important to take every necessary safety precaution. For vapor degreasers, one of the most important considerations is ventilation. Many degreasing solvents are heavier than air, thus the vapor tends to sink downward. With that in mind, a floor draft system is recommended. Furthermore, solvent is a little bit different. Fortunately all solvent shipments are required to include the Safety Data Sheet, so specific handling/usage instructions can be found within that document.

Is Vapor Degreasing Right for Me?

In most industrial applications, the answer is yes. Vapor degreasers are ideal for cleaning parts and components with deep crevices, ridges, bumps, threading or any other area where grime can accumulate. The benefit of vapor is that it can get into those hard-to-reach spaces to ensure a thorough cleaning.

Who Benefits From Using Vapor Degreasing?

Virtually any industry or shop that needs to deep clean parts or components stands to benefit from vapor degreasing equipment. Standard cleaning processes are incredibly time-consuming and not nearly as effective as vapor degreasing. Solvents used in the degreasing process also are exceptionally stable, which means they can be used many times and still remain effective. This gives large manufacturers in aerospace, metal finishing and other industries the opportunity to save money with volume purchases.

What Are the Benefits of Vapor Degreasing?

There isn’t enough space on this page to cover all of the benefits of vapor degreasing. But to cover the highlights, vapor degreasing is highly effective. It traps and removes soils that you might otherwise never see. It’s efficient. The time and money saved from automated vapor degreasing can be used to better support your other business priorities.

How Do You Select a Vapor Degreasing Solution?

You have a few options when it comes to vapor degreasing solutions. Each has its benefits, and some are specific to the material you’re cleaning. For example, n-propyl bromide solvents have properties such as rapid evaporation, which make them ideal for the high tech industry. In short, you want an option that is effective without damaging the surface of your components. That means balancing cleaning power with solvency. Consult with an Enviro Tech expert to determine which vapor degreasing solution is best suited to your application.

How Do You Set Up a Vapor Degreaser?

Vapor degreasers are complex machines, but installing them in your manufacturing facility should be relatively simple. We recommend consulting with an Enviro Tech expert and your fire marshal to ensure that your equipment is set up properly and safely. It’s also essential to prioritize ventilation when you install a vapor degreaser. Leverage a draft system and consult an on-the-ground safety expert to ensure that you are fully compliant with all applicable codes and regulations.

Where Should a Vapor Degreaser Be Located?

While a convenient location near floor operations is ideal, safety should be your top priority when deciding where to place your vapor degreaser. Because ventilation is essential, avoid areas with a cross draft, such as near an air-conditioning unit, fan or window. Similarly, consider a location where you can control humidity levels, as some solvents react negatively with water and can become acidic. Finally, place your vapor degreaser where it does not block emergency access or evacuation routes.

How Do You Handle and Store Solvent?

As with any industrial chemical, you must be extremely careful when handling solvents. Solvents are strong chemicals that can irritate skin, and the vapors can be hazardous if left unchecked. Use protective clothing and gloves as necessary. In terms of storage, be sure to keep your solvents in a well-ventilated space away from open flames. For additional handling/storage instructions, please refer to the Safety Data Sheet that was included with the solvent purchased.

Are There Regulations Regarding Vapor Degreasing?

Yes. Your vapor degreaser equipment must comply with local permitting and code requirements. In terms of the solvents, many are regulated for safety and environmental impact. Not all chemicals are subject to the same level of regulatory oversight, so be sure to consult with Enviro Tech or your fire marshal to be sure you’ve checked all the boxes.

As you can see, selecting and placing your vapor degreaser is a multifaceted undertaking. You’re going to have plenty of questions along the way, but this guide can start you on the right path. Of course, the team at Enviro Tech is ready to help you make the right choice for your application. Check out our selection of vapor degreasing equipment and products, and contact us today to learn more about how vapor degreasing can improve your operations.